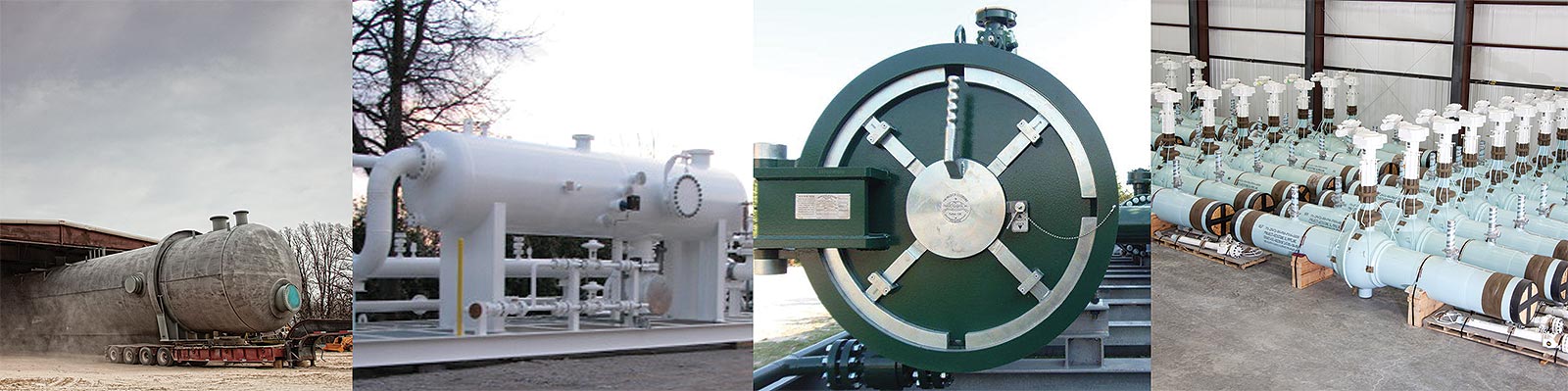

Coating

PEI Industrial Coating provides sandblasting, painting and coating support to the other PEI Divisions and to other area manufacturing and fabrication facilities.

This facility features more than 30,000 sqft with expanded heavy lifting capabilities, climate controlled paint spaces and an independent sandblast structure. We can spray both single and multi component coating products as well as 100% epoxy plural component. We have experience in above and below ground coating with internal and external applications. PEI Industrial Coating employs an experienced NACE Certified Coating Inspector. PEI Industrial Coating has the facilities, equipment and experience to meet your coating requirements and specifications.

We Sandblast AND coat a wide variety of products including:

- Launchers & Receivers

- Mainline Valve Settings

- Meter Tubes & Skids

- Inlet & Outlet Headers

- Structural Steel

- Pressure Vessels

- Bulk Storage Tanks

- Manifolds

- Fabricated Steel Structures

- Dehydrator Vessels

- Pumps & Mixers

- Valves

SANDBLASTING:

Sandblasting allows us to remove old coatings, rust and other contamination in preparation for new, high quality coating. We blast with a variety of media, including:

- Silica Sand

- Black Beauty

- Sugar

- Soda

- Ground & Bead Glass

- Garnet

Application Experience with:

Single & Multi Component

- Alkyd Enamels

- High Temp Silicones

- Epoxy Novolacs

- Polyurethanes

- Zinc Rich Epoxy

- Coal Tar Epoxy

- Epoxies Mastics

- Vinyl Esters

- Lacquers

- Inorganic Zinc

- Flake Filled Epoxy

- Epoxy Phenolics

- Scotchcote 323

Plural Component

- SPC-2888

- SPC-4888

- SPC-7888

- SPC-8888

- Denso 7200

*additional blast media and coating available on request.